Chemical Industry : rotors, stators for injection and commutation valves

Medical : Dental implant, special surgery tools, ceramic dental brackets….

Microtechnic : Watch parts, zirconium oxide wire guides, and so on…

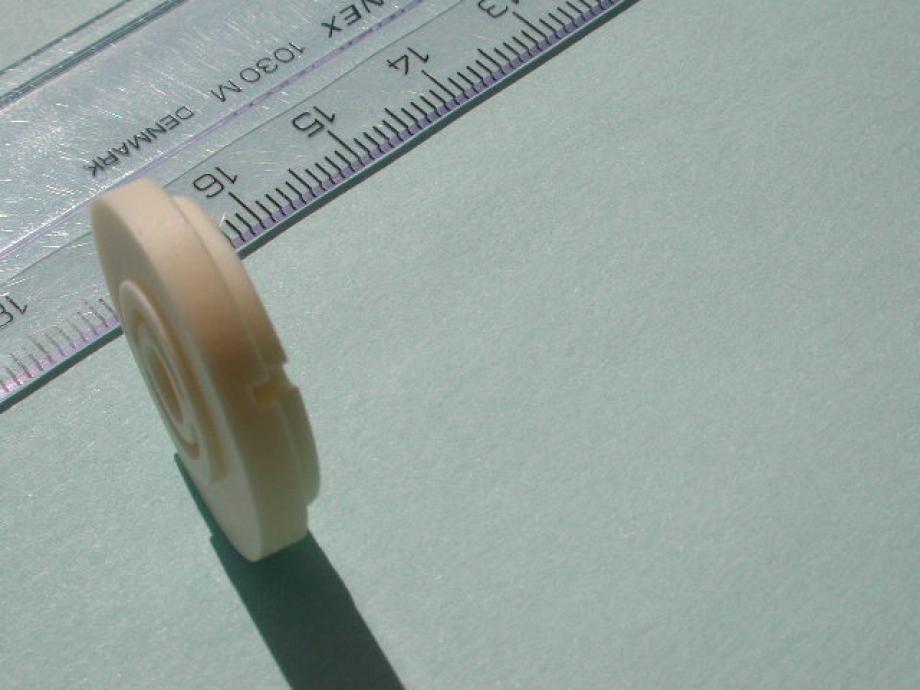

Industrial equipment : zirconia Nozzles, thread Guides, pivot, spinning parts, ceramic cutters, investment casting core,…

Ceramic Bottle-Neck (BTNK) Capillary for wire Bonding

Others : model-making ceramic parts, jewels, weave machine wear parts. advanced ceramic Nozzles for Water jet cutting, for casting, wire cutting knife, thread Guides, pivot, spinning parts, ceramic cutters, special wear resistant parts, are the actual main products.

Microtechnical

The high precise control of the shrinkage which enable us to produce sintered parts within tolerance of +/- 3 microns , the polishing of sintered ceramics up to a surface roughness of grade N1 and the capacity to mould micro ceramic components with complex shape make our ceramic molding within the specifications and the requirements of the micro-technical and the watch industry.

Application domains : Watch pieces (moving parts under abrasive wear, case, …) , micro parts, micro tube , ceramic guide, ceramic rotor stators for micro-pump, ring.

Chemical Industry

Where materials are in contact with aggressive chemical and high thermal environment Alumina and Zirconia are well suited.

Melting crucibles , nozzles for casting, small nozzles with microns tolerances, Check valve for HPLC, rotors , stators for injection and commutation valves are mainly made out of Alumina, zirconia, or others oxide ceramics.

Dental industry

The high Bio-compatibility and the very good chemical resistance of the technical ceramics specially the Zirconia which additionally develops good mechanical resistance explain the growing of the use of the zirconium oxide material for medical application.

Orthodontic brackets, Dental implants, special surgery tools are the main products. Other requirements are welcome.